Batch-to-Batch Difference

What is Batch-to-Batch Variation in Chemical Raw Materials and How to Minimize It?

Batch-to-batch differences are physical or chemical changes, even small ones, seen in different production lots of the same product.

Even if a raw material is produced with the same formula , the same process and the same raw material source every time — differences at the micro level are inevitable.

For example;

-

density +/- 0.2% difference

-

very slight yellowing in color tone

-

very little change in odor

-

± 3% fluctuations in viscosity

These all fall into the category of batch-to-batch difference.

These differences can affect the manufacturer's formula results, especially in sectors such as cosmetics , cleaning , polymers , and aroma-essences .

Why Does It Occur?

There are several main reasons for the batch difference:

1) The raw material is of natural origin

e.g.: glycerin, castor oil, fatty acids, essential oils

“Natural variation” is very normal in plant-derived products.

2) micro-differences in process parameters

such as temperature / time / rpm / vacuum / reaction termination

3) Storage & transportation conditions

light – temperature – humidity

4) Lot difference of additives used

antioxidant, stabilizer, solvent etc.

How much is considered “normal”?

Manufacturers usually write limits in their specifications:

-

pH: 6.0 – 7.0

-

color: max 20 Hazen

-

viscosity: 4000 – 4500 cP

like…

Differences within this range are considered commercially normal .

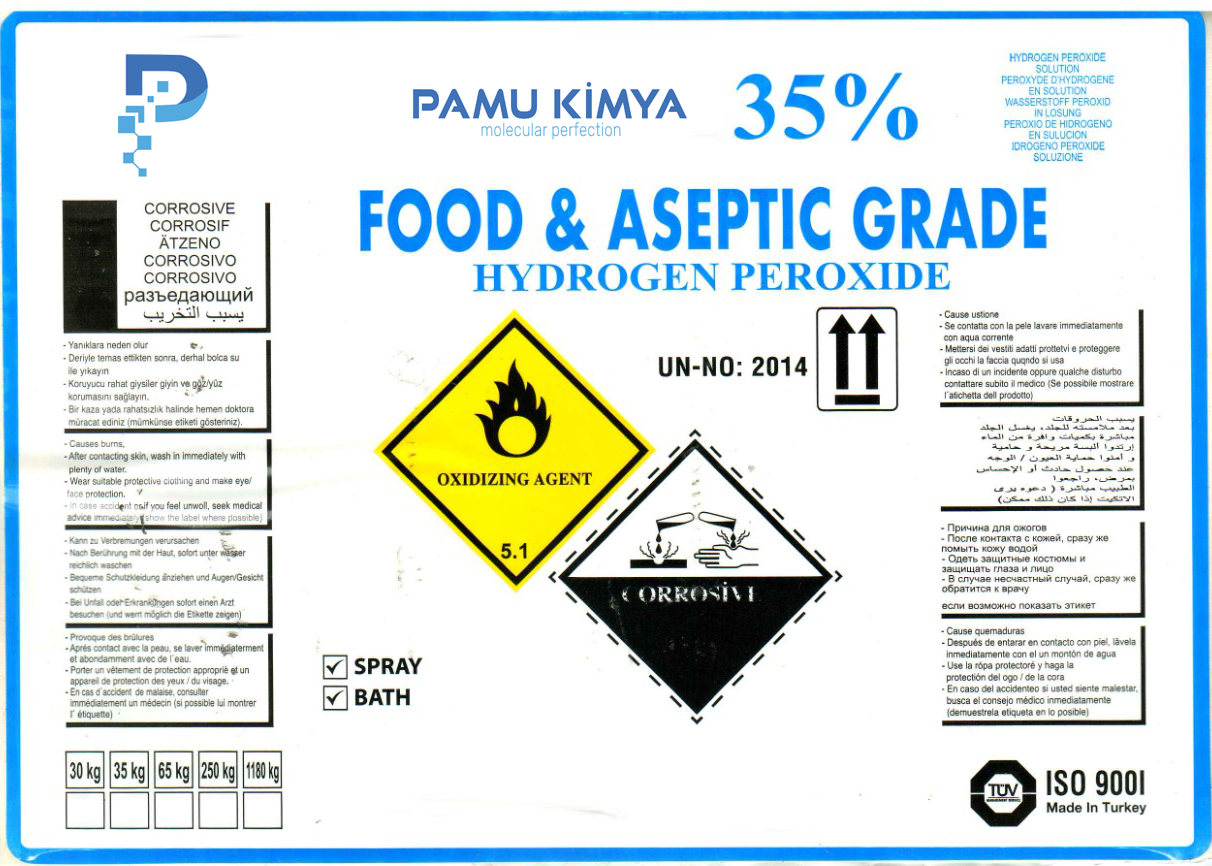

Suppliers like Pamu Kimya share batch specifications along with CoA when selling products.

In this way, the buyer can clearly see where the product lot is located.

How to Minimize These Differences?

1) CoA check on every delivery

this is the most critical step.

Before the product enters the stock, it is checked whether it meets the specifications.

2) Lot pooling in large producers

3-4 batches of the same product are mixed → single tone / uniform quality is obtained.

(this is especially used in soap, detergent and perfume concentrate manufacturers)

3) leave tolerances in production recipes

Designing a recipe based on “viscosity + 3% variation”.

4) securing the supplier

different vendor → different process → larger batch difference risk.

In the long run, following the same source generally yields the most stable results.

5) Keeping stock periods short

Waiting time affects quality, especially in oils, esters and essences.

The standard approach applied by Pamu Kimya

Pamu Kimya, in its raw material shipments:

-

lot-based CoA

-

specification sheet

-

sending samples when necessary

It aims to ensure that the batch difference does not come as a "surprise" to the buyer.

Since many customers prefer to stay with the same product in the same process , quality fluctuations throughout the year are minimized.

Conclusion

Batch-to-batch difference is a completely natural phenomenon.

The important thing is to control this difference and make it predictable .

With CoA tracking + fixed supplier + lot pool approach

Product formulas are more stable and production runs smoother.