Paints

Chemistry of Paints: Where Colors Meet Science

Pamu Chemistry Blog

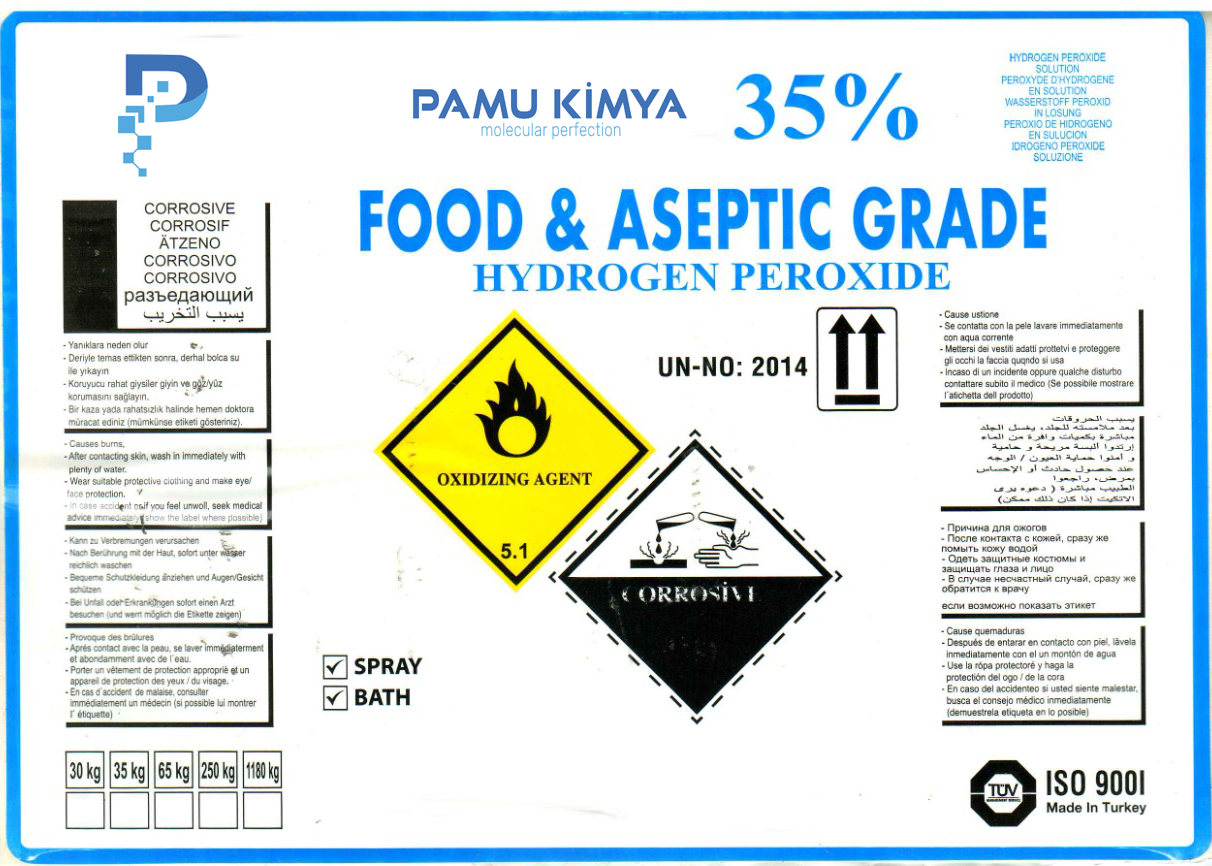

Colors are present in every aspect of our lives: on our walls, in our cars, in our clothes, even in cosmetics. However, the scientific processes behind this colorful world occupy a profound and intriguing place in the field of chemistry. At Pamu Kimya, we share with you the fundamental building blocks, types, and formulation processes of paint technologies.

1. What is Paint?

Paint is a mixture of pigments, binders (resins), solvents, and additives, usually in liquid or powder form, applied to decorate, protect, or mark surfaces. After application, it dries to form a hard, durable film.

2. Chemical Components of Paints

The chemical structure of a paint generally consists of four main components:

-

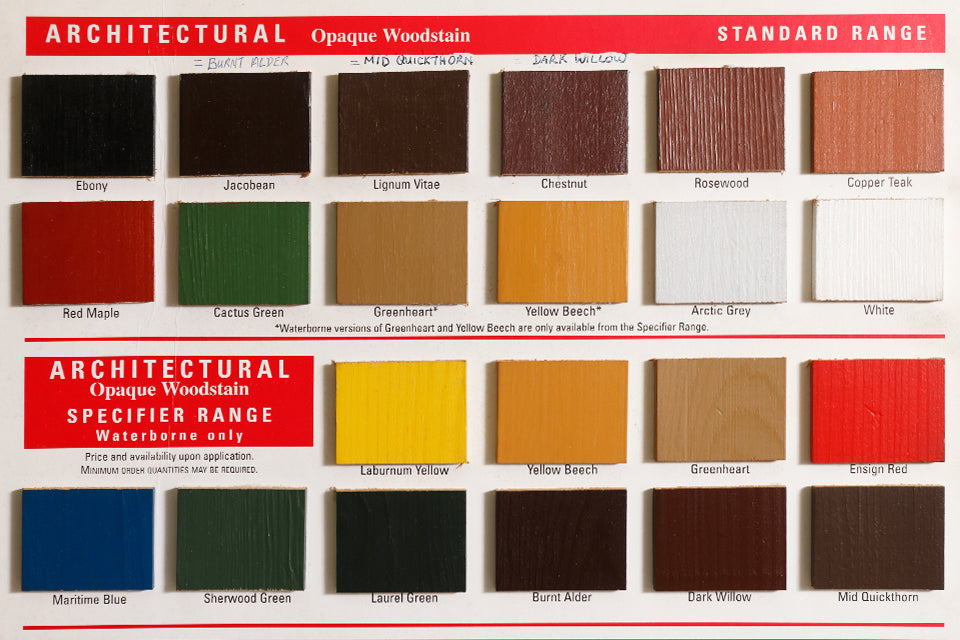

Pigments: Powdered inorganic or organic substances that impart color. For example, titanium dioxide (TiO₂) provides white pigment, and iron oxides provide red, yellow, and brown pigments.

-

Binders (Resins): These are polymeric materials that bind pigments to the surface. Acrylic, alkyd, epoxy, and polyurethane-based resins are the most common.

-

Solvents: Adjust the viscosity of the paint, making it easier to apply. They can be water-based (acrylic) or solvent-based (thinner, etc.).

-

Additives: These are substances that adjust drying time, reduce surface tension, increase UV resistance or prevent fungus and mold formation.

3. Paint Types and Areas of Use

At Pamu Kimya, we develop a wide range of coating solutions for various industries. Some of these include:

| Paint Type | Area of Use | Chemical Properties |

|---|---|---|

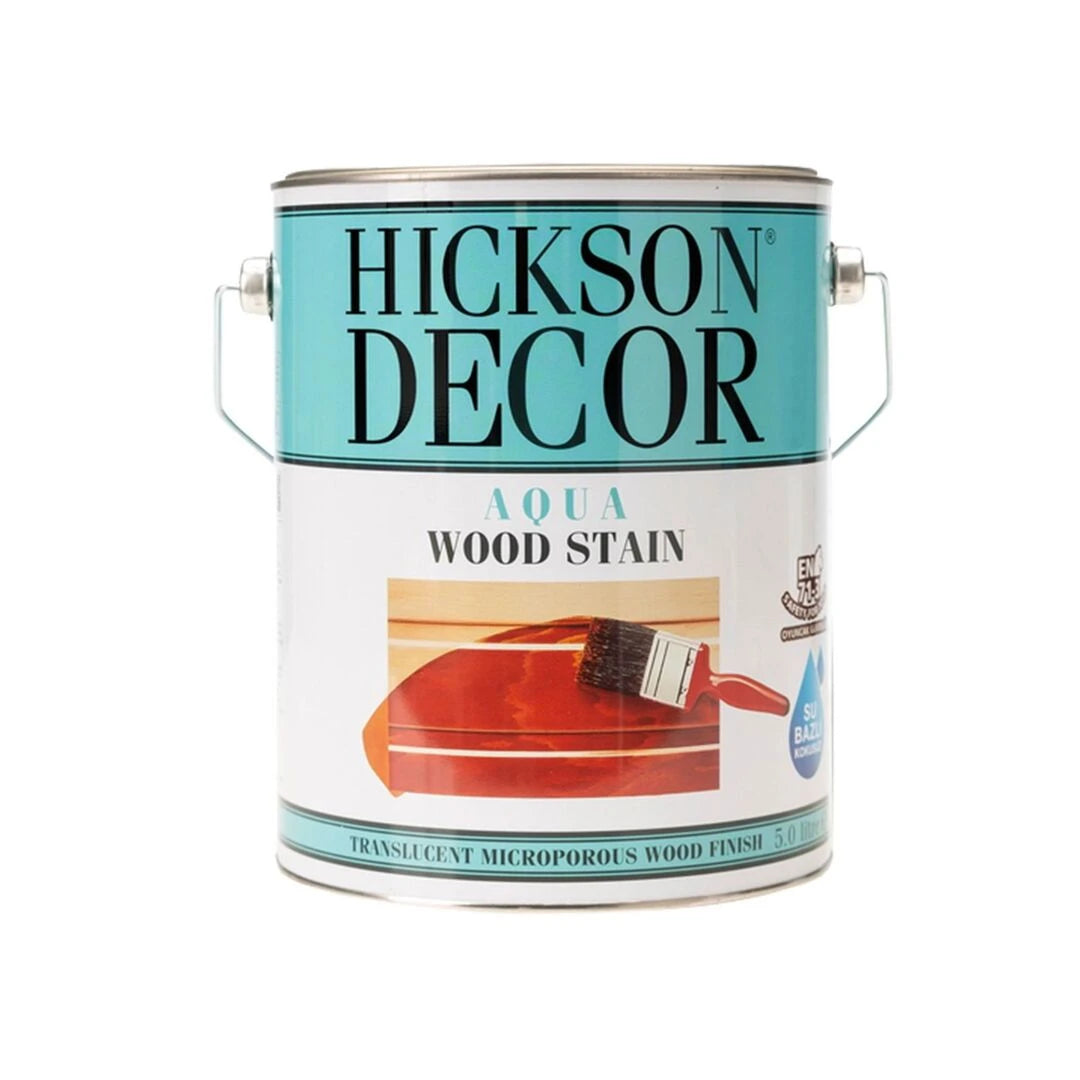

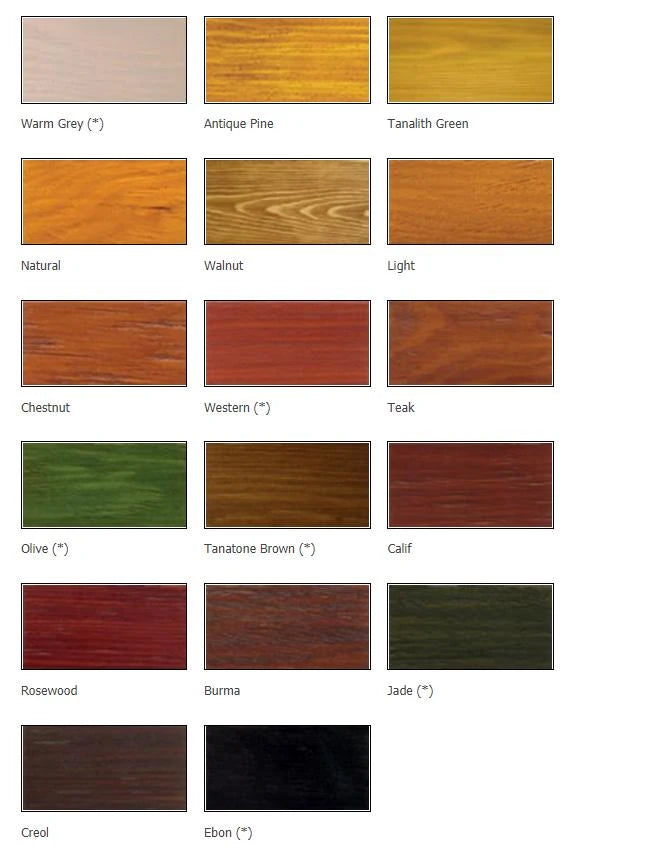

| Water-Based Paints | Interior and exterior facades, wood, metal surfaces | Environmentally friendly, low VOC |

| Solvent Based | Automotive, industrial machinery | High adhesion strength and gloss |

| Epoxy Paints | Floor coverings, industrial areas | Resistant to chemicals |

| Polyurethane Paints | Furniture, automotive, wooden surfaces | High scratch and UV resistance |

| Powder Paints | White goods, metal plating | Solvent-free, electrostatically applied |

4. Environmentally Friendly Paint Technologies

Today, with environmental awareness, water-based, biodegradable paint formulations with low VOC (volatile organic compound) content have gained importance. At Pamu Kimya, we have adopted the principle of creating sustainable solutions. The paints we develop accordingly:

-

It is water-based and odorless.

-

It is offered in recyclable packaging.

-

It does not contain heavy metals harmful to human health.

5. Paint Production Process

Paint production is a process in which delicate chemical balances are established and technology is closely monitored:

-

Formulation Development: A recipe appropriate to customer needs is determined.

-

Distribution and Grinding: Pigments and additives are ground to the micron level.

-

Mixing: A homogeneous mixture is obtained.

-

Filtration and Filling: Foreign materials are separated and the product is packaged.

-

Quality Control: Tests such as viscosity, color, gloss and drying time are applied.

6. Pamu Kimya's Contribution

At Pamu Kimya, we don't just produce paints; we also offer our customers custom formulations, R&D support, technical consulting, and high-performance solutions. We prioritize quality, the environment, and aesthetics.