Quality Control Processes

What Should Quality Control Processes Be Like in Chemical Products?

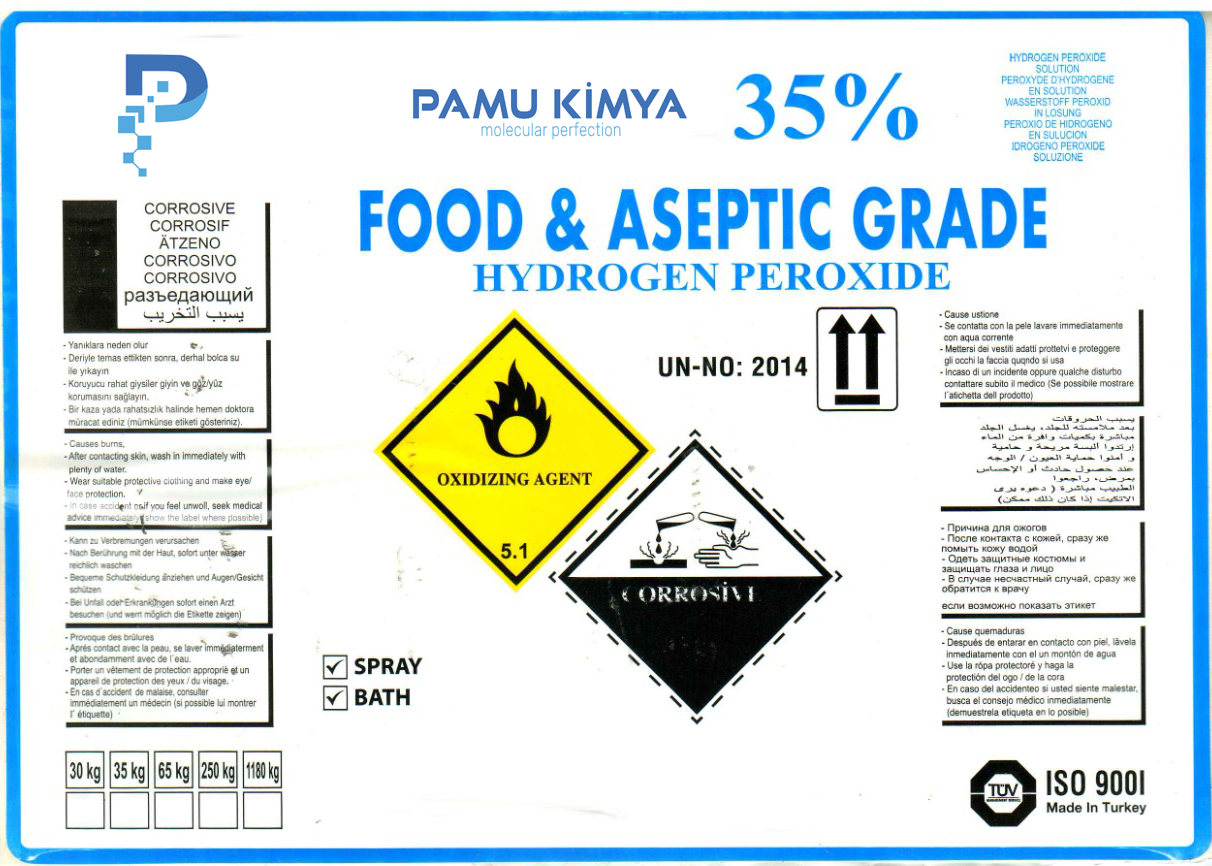

In the chemical industry, product quality directly impacts not only customer satisfaction but also human health, environmental safety, and regulatory compliance. Therefore, implementing an effective quality control (QC) process at every stage of production is crucial.

At Pamu Kimya, we approach quality not simply as an outcome, but as a process managed at every stage. Here are the fundamental steps of an effective quality control process for chemical products:

1. Input Quality Control (Raw Material Inspection)

Quality is shaped at the point where production begins. Therefore, the raw materials used:

- Certificates (CoA),

- Chemical analysis results,

-

Supplier reliability,

should be checked in advance. Unsuitable inputs should be separated immediately and not introduced into production.

2. Process Control (Production Process Monitoring)

During production, critical parameters such as temperature, pH, viscosity, and density must be constantly monitored. This data, tracked by automated systems, enables immediate intervention in the event of deviations.

3. Intermediate Product and Sample Tests

Samples taken during production are tested in a laboratory environment to ensure compliance with product standards. These tests include:

- Titration,

- Spectrophotometry,

- It may include methods such as FTIR or GC-MS analysis.

4. Final Product Quality Control

After production is completed, the product undergoes physical, chemical, and microbiological tests before shipment. At this stage:

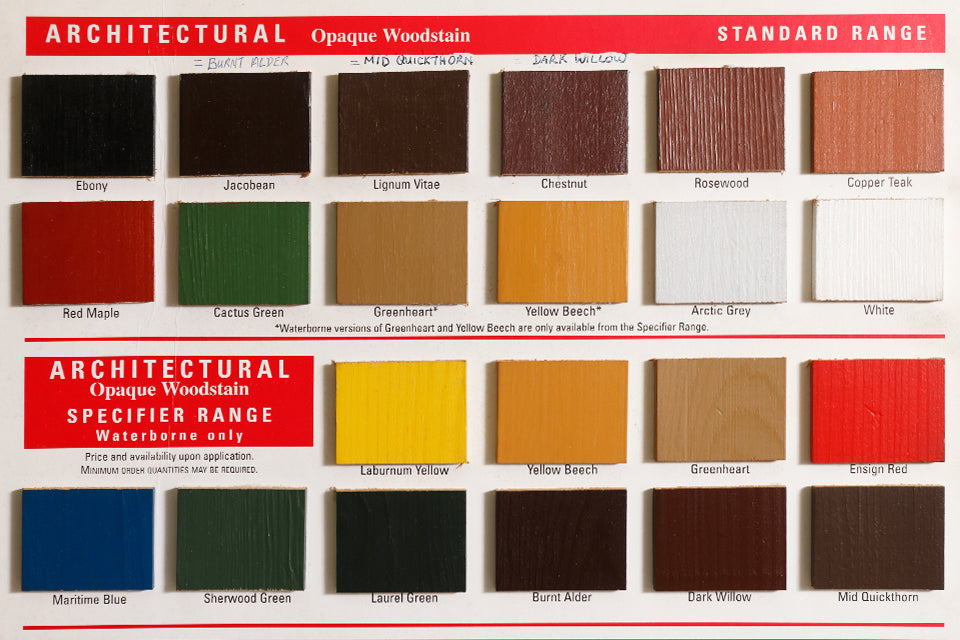

- Physical properties such as color, odor, consistency,

- Active ingredient ratio,

- Shelf life preliminary tests are evaluated.

5. Documentation and Traceability

Keeping records of each test, its results, and the person who performed it ensures traceability and transparency against regulatory audits. The quality control process should include:

- Test reports,

- Lot number based tracking systems,

- Product release documents.

6. Feedback and Continuous Improvement

Customer complaints and quality deviations should be analyzed and feedback provided to the process. Thus, quality control becomes not only a control process but also a part of the continuous improvement (Kaizen) process.

7. Compatible Test Equipment and Calibration

Test devices used in the laboratory:

- Regular calibration,

- Use by certified personnel,

- Supporting with redundant systems increases quality control reliability.

Conclusion: Quality is not a coincidence, it is a system work.

In the chemical industry, quality control isn't just a final step; it's a strategic approach encompassing the entire process, from design to shipment. Safe, effective, and sustainable products are only possible through systematic quality management.

As Pamu Kimya, we instill confidence in both our business partners and the end user by adopting this quality control discipline in all our production steps.