Protection on Metal Surfaces

Metals are widely used in industry for their durability and conductivity. However, moisture, oxygen, and chemical interactions can cause corrosion and rust over time. This shortens product lifespan and leads to economic losses.

1. Physical Methods

-

Paint and Varnish Coating: Protects the metal surface by isolating it from external factors.

-

Galvanizing (Zinc Coating): It is the most common method, especially for steel and iron.

-

Anodic Oxidation (Anodization): Increases the durability of aluminum surfaces.

-

Coating Materials: Creating a barrier with plastic, resin or enamel.

2. Chemical Methods

-

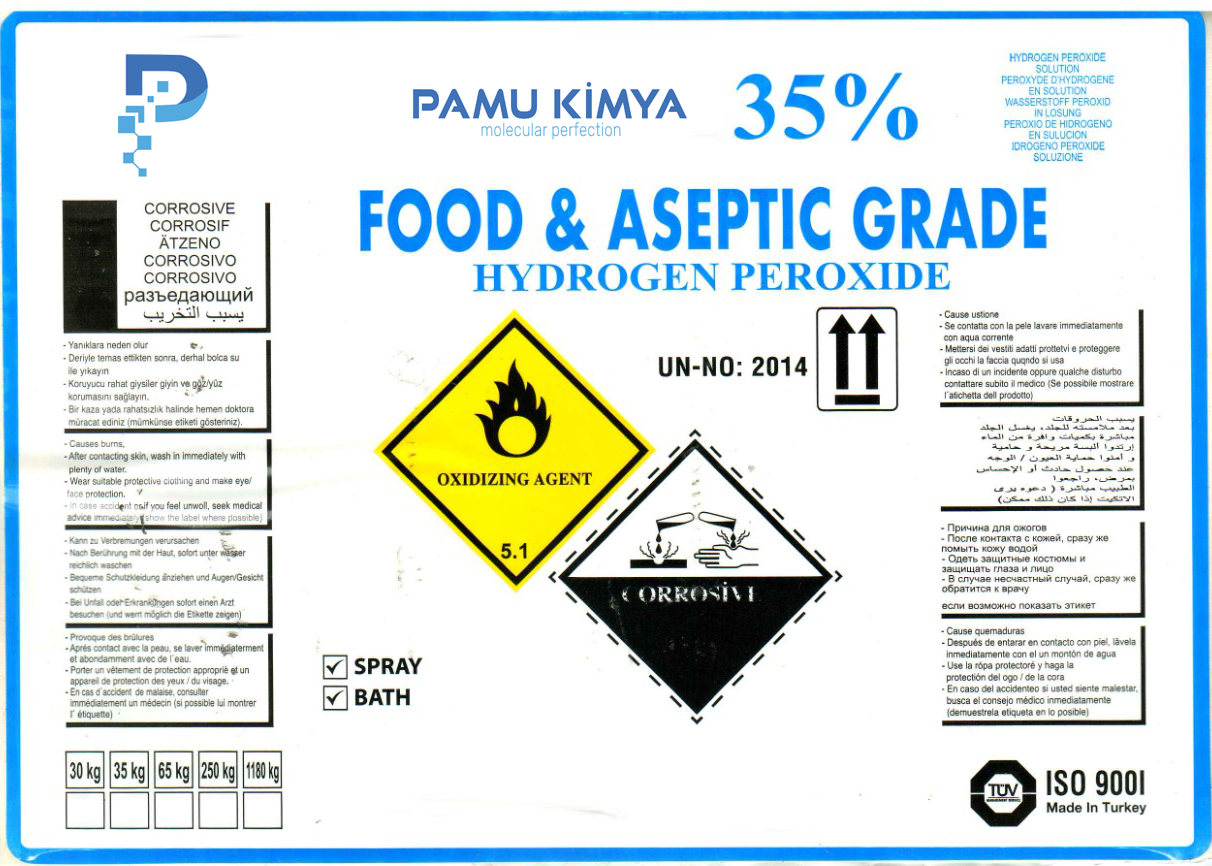

Corrosion Inhibitors: Chemicals that slow down reactions between the metal surface and the environment (example: nitrites, phosphonates).

-

Passivation: Formation of a thin protective film on the metal surface with acidic solutions.

-

Cathodic Protection: Providing protection by bonding a more active metal (zinc, magnesium) to the metal surface.

3. Electrochemical Methods

-

Cathodic Protection (Galvanic Anode): Frequently used in pipelines and tanks.

-

External Current Cathodic Protection: Corrosion is prevented by using an energy source.

4. Modern Solutions

-

Nano Coatings: Long-lasting protection with hydrophobic and super-thin films.

-

Smart Coatings: Polymer-based coatings that can repair themselves even if scratched.

-

Environmentally Friendly Corrosion Inhibitors: Phosphonate and organic-based inhibitors instead of traditional heavy metals.

Conclusion

Protecting metal surfaces is critical for both extending product life and reducing maintenance costs. The right combination of physical, chemical, and electrochemical methods, tailored to your needs, provides the most effective results.