Advantages of Powder Coating

The advantages of powder coating cover a wide range from sustainable production to high quality. The reasons why this modern coating method is preferred in industrial applications are:

●Powder coating does not contain VOCs (Volatile Organic Compounds) compared to traditional liquid paints, meaning less environmental impact.

●Thanks to waste minimization, recycling of unused powder paint is possible, which reduces material waste and lowers costs.

●Powder coating provides excellent adhesion to surfaces, providing superior protection against abrasion, scratching and fading.

●Lower cooking temperatures and shorter cooking times reduce energy consumption.

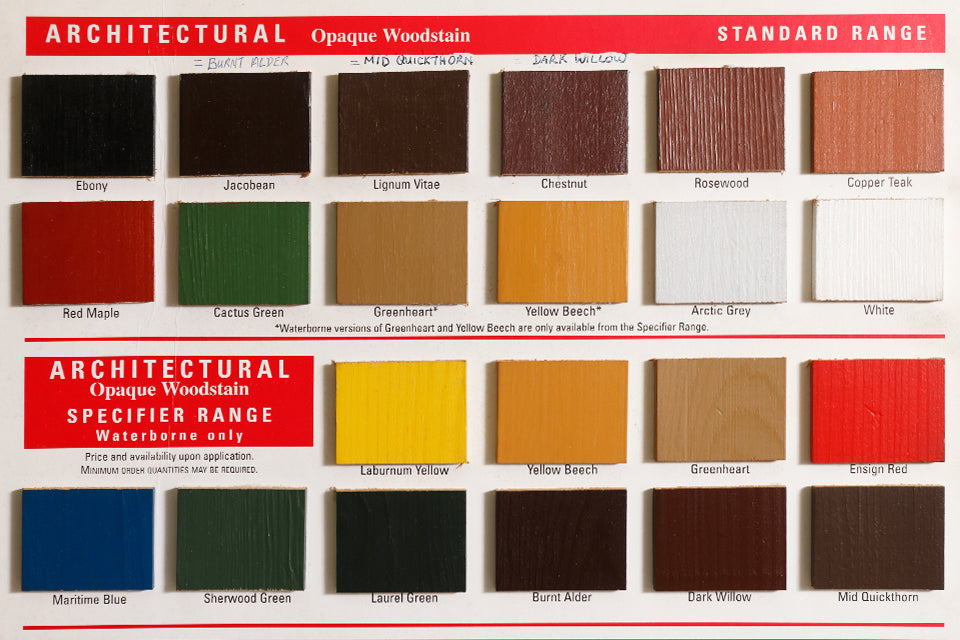

●Powder coating provides options in a variety of colors and textures that appeal to consumer preferences.

●Powder coating saves time in production processes by offering a practical and fast application.

●Ideal for thick coating needs and can be applied without dripping or running.

Powder coating and sustainability have led to the expansion of the powder coating market sector today, where environmentally friendly production processes have gained importance. This coating method reduces VOC emissions to zero with its solvent-free formula, while minimizing waste with the reusability of waste materials. The energy efficiency and long-lasting coating features offered by powder coating manufacturers further reduce the environmental impact of powder coating.

Powder coating technology is creating a green revolution in the industrial coatings industry by adopting sustainable production methods. It is attractive to environmentally conscious consumers due to its features of extending the life of products and reducing maintenance needs. These features are among the key factors supporting the future market growth of powder coating.